Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: TC-1080Z

Brand: Innovo

Types Of: Laminating Machine

Applicable Industry: Hotels, Food &Amp; Beverage Factory, Food Shop, Printing Shops, Energy &Amp; Mining

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 2 Years

Core Components: Plc, Engine, Bearing, Gearbox, Motor

Status: New

Application: Food, Commodity, Chemical, Machinery &Amp; Hardware

Type Of Packaging: Cartons, Bottles, Stand-Up Pouch

Packaging Materials: Plastic, Paper

Degree Of Automation: Automatic

Power Type: Electric

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Supply Ability & Additional Information

Packaging: wooden case

Productivity: 50 sets/month

Transportation: Ocean

Place of Origin: Zhejiang,China

Supply Ability: 50 sets/month

Certificate: CE

Payment Type: T/T,L/C,Western Union

Incoterm: FOB

Product Description

TC-1080Z Automatic Window patching machine.

Product features:

TC-1080Z Automatic window patching machines are special equipment for carton box, color box window lamination; They are advanced models in domestic market. Perfect design ensure the machines have the feature of high efficiency, high-precision, high stability and easy operation.

These machines are available for both cardboard and corrugated paper.Like tissue boxes, gift boxes, toy boxes, shirt boxes, milk cartons and so on.

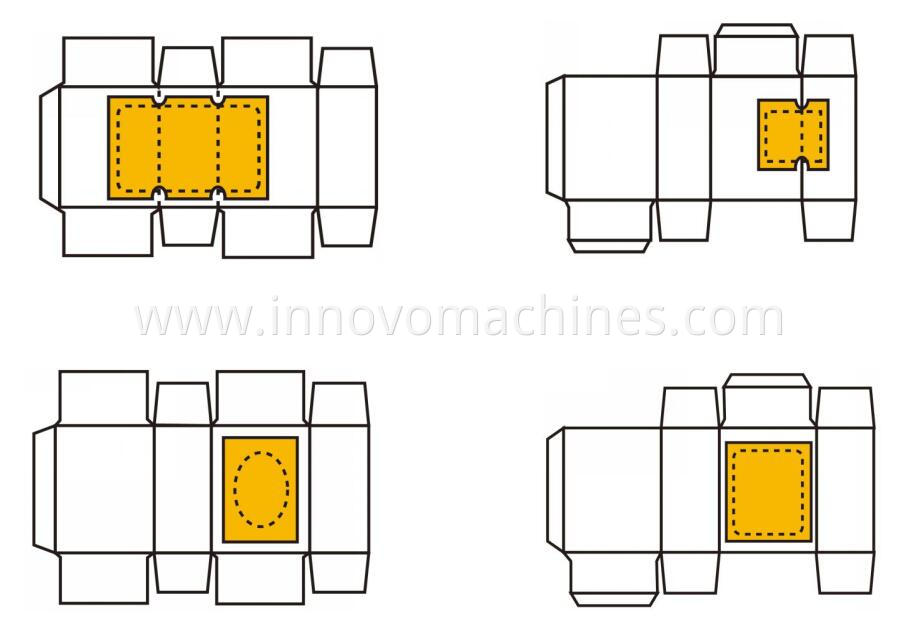

Product types:

Technical specification:

| Model | TC-1080Z |

| Max paper size(mm) | 1080*650 |

| Min paper size(mm) | 100*100 |

| Max window size(mm) | 580*450 |

| Min window size(mm) | 40*40 |

| Cardboard (g/㎡) | 200-1000 |

| Corrugated paper(mm) | ≤4.0 |

| Precision(mm) | ± 1.5 |

| Film thickness | 0.05-0.25mm |

| Max working speed(s/h) | 5000-7000 |

| Total power (kw) | 10 |

| Total weight (T) | 3.3 |

| External dimension(mm) | 4958*1960*1850 |

Part Introduction:

1.Special design for die-cutting angles&Creasing:

◆ Creasing section is equipped with independent heating wheels for creasing.

◆ There is an independent cylinder heated by oil to flatten the curved plastic film.

◆ Equipped with corner cutting system controlled by servo to make the plastic film smooth.

◆ Equipped with micro-adjusment system, easy to operate.

2.Feeder:

◆ The unique supporting plate and wheel feeding type replaces the servo intermittent feeding type.

◆ Ensure that the paper is smooth

◆ Deliver the paper with high speed,stable and reliable.

◆ Our company has won the national patent for this part.

3.Rotation rubber roller(can pull-out):

◆ Single rubber roller cooperate with baffle to gluing.

◆ Avoid the waste of glue,reduce the volatilization.

◆ When the machine stopped,the rubber roller can rotation driving by the motor. Avoid the glue solidify on the face of rubber roller.

◆ When cleaning the rubber roller, this part can pull-out entirely,reduce cleaning time.

4.Gluing:

◆ Use automatic gluing instead of hand movement.

◆This part can adjust the glue roller right or left、up or down.

◆ When the photoelectric sensor reacted the paper. If there are papers pass,the machine will use the air cylinder to control platform to uplift.

◆ If there are no papers pass,the platform will decline.

◆Avoid the glue smear on the belt.

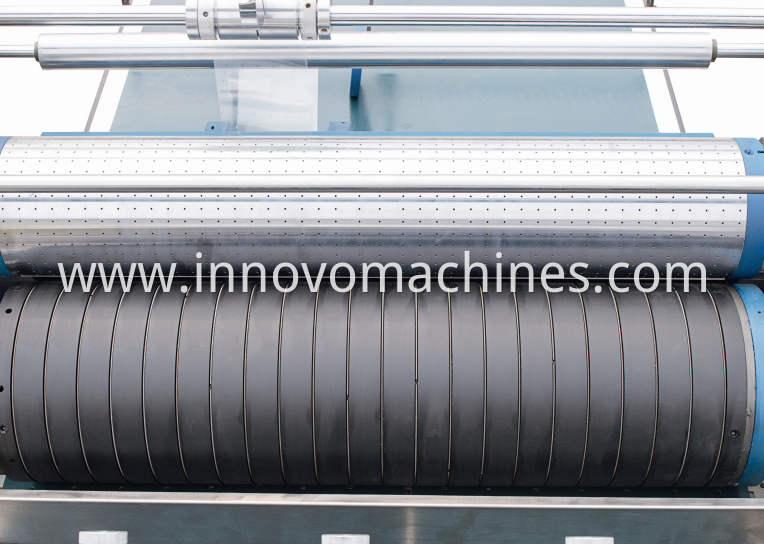

5.Suction belt:

◆ The two suction belts are wide and thick,increase service life.

◆ With the device of adjust the wind power.

◆ Can adjust wind power according to the sizes of papers.

◆ Ensure that no position offset.

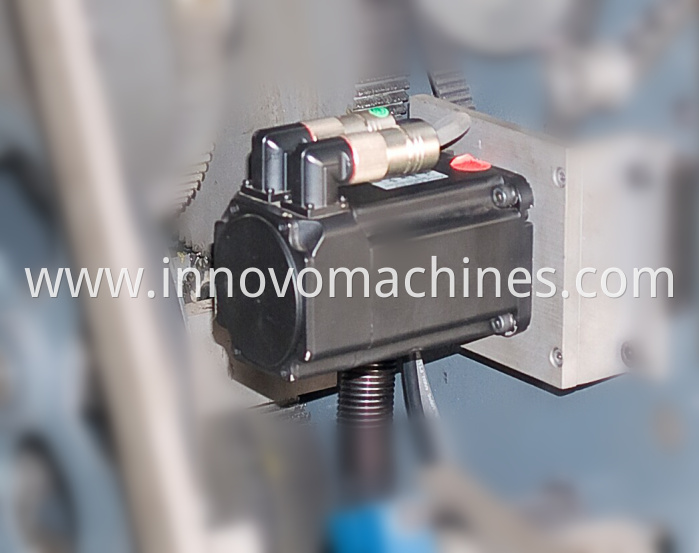

6.Film transport:

◆ Film Transport is controlled by the servo motor.

◆ With high precision,make the error of cutting the film is less than 0.5mm.

◆ Adopt the touch screen to adjust the length of the film.

◆ Make the adjustment more convenient and efficient.

7.Roller knife:

◆ Quality alloy steel was adopted special heat treatment process to ensure long working hours.

◆ Use the touch screen to set the film length.

◆ So that the machine can runs more accurate, stable and reliable.

Working area:

|

Operating conditions:

◆ Working temperature is 5ºC to 40ºC.

◆ Transportation and storage temperature is-25ºC to 55ºC.

◆ The relative temperature is not greater than 60% (20%c), and the altitude is not

more than 1000 m.

Power supply specification:

◆ Total power: 3 phase 4 wire,380V 50HZ

◆Control power: single phase,220V AC 24V DC

◆Deviation: ±10%V ±1HZ

◆Total power:10KW

Note:Due to the diversity of products, the applicability of the machine will be affected.

So the above data is not applicable to every product.

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.