Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

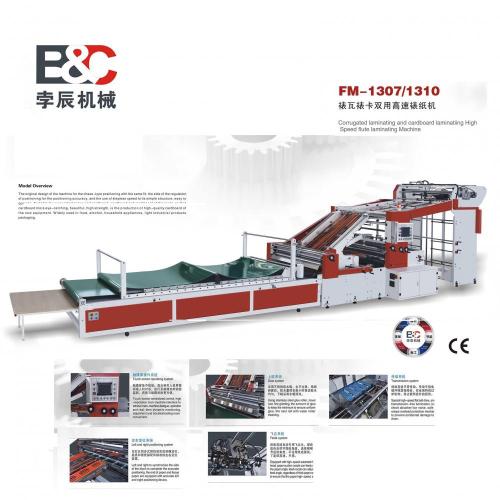

Model No.: ZX-1307

Brand: Innovo

Maximum Paper: WidthW1300mm×height700mm

Minimum Paper: WidthW500mm×height300mm

Thickness Of The Backing Paper: 300(g)~8mmThickUpto

Maximum Speed: 10000 / H

Glossy: 150(g)~700(g)

Supply Ability & Additional Information

Packaging: wooden case

Productivity: 10 pieces/month

Transportation: Ocean

Place of Origin: Zhejiang,China

Supply Ability: 10 sets/month

Certificate: CE

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

Product Description

Technical Parameter:

| Model: | ZX-1307 | ZX-1310 | ZX-1312 | |

| Maximum speed: | 10000 / h | 7800/h | 7800/h | |

| Maximum paper: | widthW1300mm×heighL700mm | widthW1300mm×heighL1000mm | widthW1300mm×heighL1200mm | |

| Minimum paper: | widthW500mm×heighL300mm | widthW500mm×heighL300mm | widthW500mm×heighL300mm | |

| The thickness of the backing paper: | 300(g)~8mmThickUpto | |||

| Glossy thick: | 150(g)~700(g) | |||

| Precision error: | ±0.55mm(Standard flat paper) | |||

| Applicable to glue: | Resin, starch, cardboard glue PH6-8 suited to fit the glue. | |||

| Machine weight: | 6500kg | |||

| Power supply: | 380V | |||

| Power: | 3P20KW | |||

| Commonly used in paper: | Tissue paper, cardboard, copper paper, paperboard, cardboard. | |||

| Applicable Products: | Thin paper and thick paper, paperboard laminating, cardboard fit by imprinted, made the tag, elevator, packaging boxes, gift boxes, phase, toys and so on. And suitable for high-intensity single-sided corrugated paper, A, B, E, F, waves, three five-story corrugated paper mounted. | |||

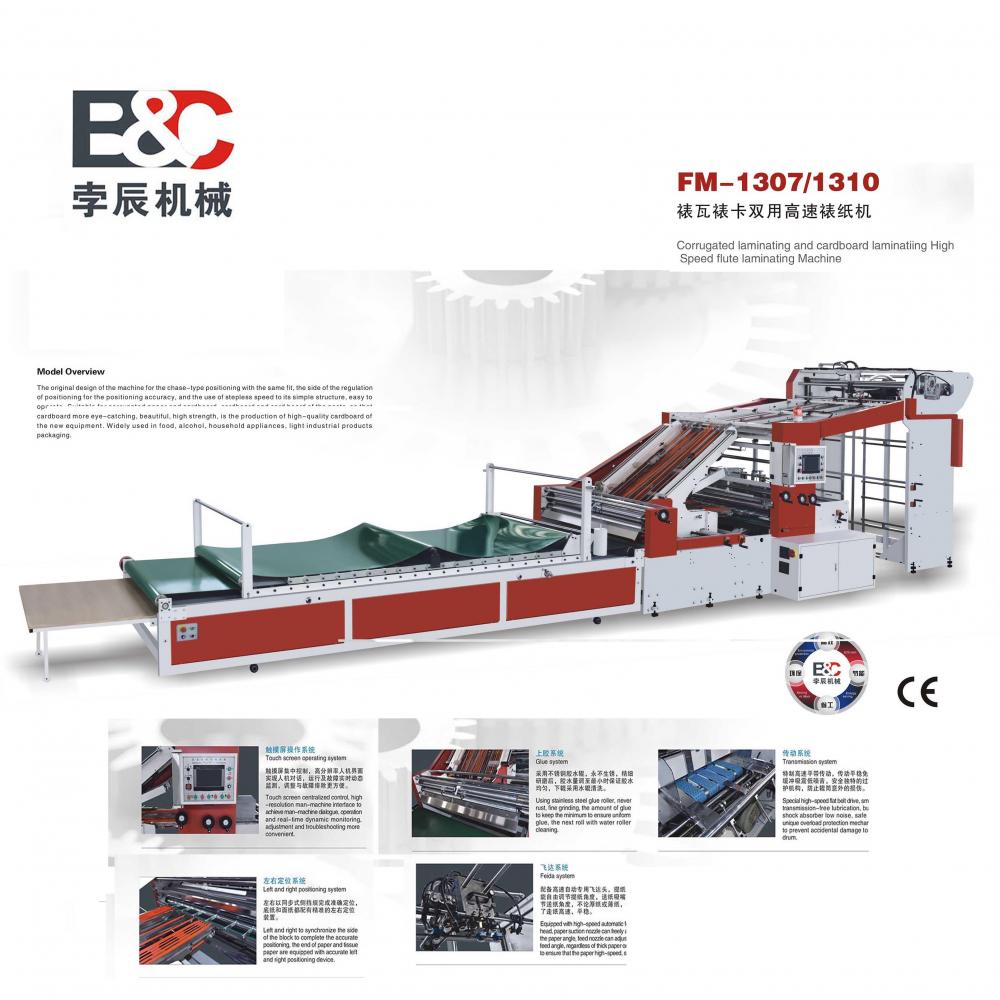

Descriptions for the series products:

1. The process of all the boards and walls of the series products are completed in one time by large machining center which can ensure the precision of all stations and the equipment operates more steadily.

2. The paper advance mechanism of facial tissue: We can ensure the paper feeding is in high speed and steady whether for thick paper or thin paper for the application of high speed dedicated Feeding Head.

3. Elevating stage of facial tissue: In line with the high speed FeiDa, We adopt high strength turbine reducer which can ensure the stability of accelerating instantly.

4. The paper supporter of facial tissue: We adopt the unique designation of E-type double gap which can push the produced paper directly with hand fork lifter, shorten the time of stacking paper and improve efficiency.

5. Body paper system: We adopt servo motor control system which have features of high sensitivity, high speed and can ensure the body paper output smooth, no jam.

6. Adsorption system of body paper: We adopt the inverter control which cooperates with the solenoid valve`s speedy switch to ensure the body paper is adsorbed completely and the operation is simple.

7. Glue wheel: The glue wheel is made by steel with thickening electroplating and the surface is treated as fine grinding. The amount of glue can be adjusted to 8g/㎡ to ensure the glue is even for thick paper and thin paper.

8. Supplement of glue: We adopt automatic level control to ensure the supplement of glue is automatic and the production is continuous.

9. Paper separation: We adopt the disengaging pawl to its high speed movements and make the paper separate from the glue wheel effectively after being daubed glue.

10. Fit orientation: We adopt the prelocalization and both sides have their own side board to ensure the high speed fit precision.

11. Driving system: We adopt synchronous belt drive imported from the United States to ensure the transmission is accurate, steady and has low noise.

12. Operating system: The equipment takes the man-machine touch screen as a operation center which is contacted with PLC, so that kinds of information, such as warning, detective hitch, abnormal condition and operating speed can be displayed on the screen, it`s absolutely clear. This can also detect maintenance log book, logging and look over in real-time, dispose timely which can truly reflects the efficiency.

13. Electric system: We adopt domestic and international famous brand, design in accordance with the European CE standard, manufacture meticulously to ensure the overall unite is stable, has high efficiency and low hitch.

14. If the machine arrangement is changed without prior notice.

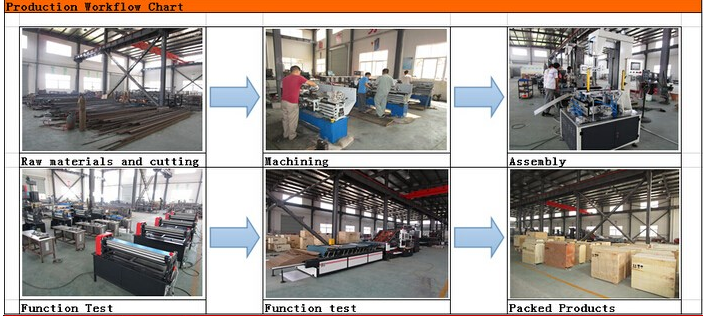

More pictures of producing,packing,company documents

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.