Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: ZGFM-1450

Brand: Innovo

Driven Type: Electric

Classification: Pre-Coating Laminating Machine

Application: Soft Board

Automatic Grade: Automatic

Membrane Material: Matt Film

Plastic Film Mulching Modes: Hot Laminating

Paper Size: A4

Warranty: One Year

Driven Type:: Electric

Model No.:: Zgfm1450

Performance:: Waterproof

Supply Ability & Additional Information

Packaging: wooden case

Productivity: 3

Transportation: Ocean

Place of Origin: Anhui China

Supply Ability: 3

Certificate: CE

Port: Shanghai,Ningbo

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,FOB

Product Description

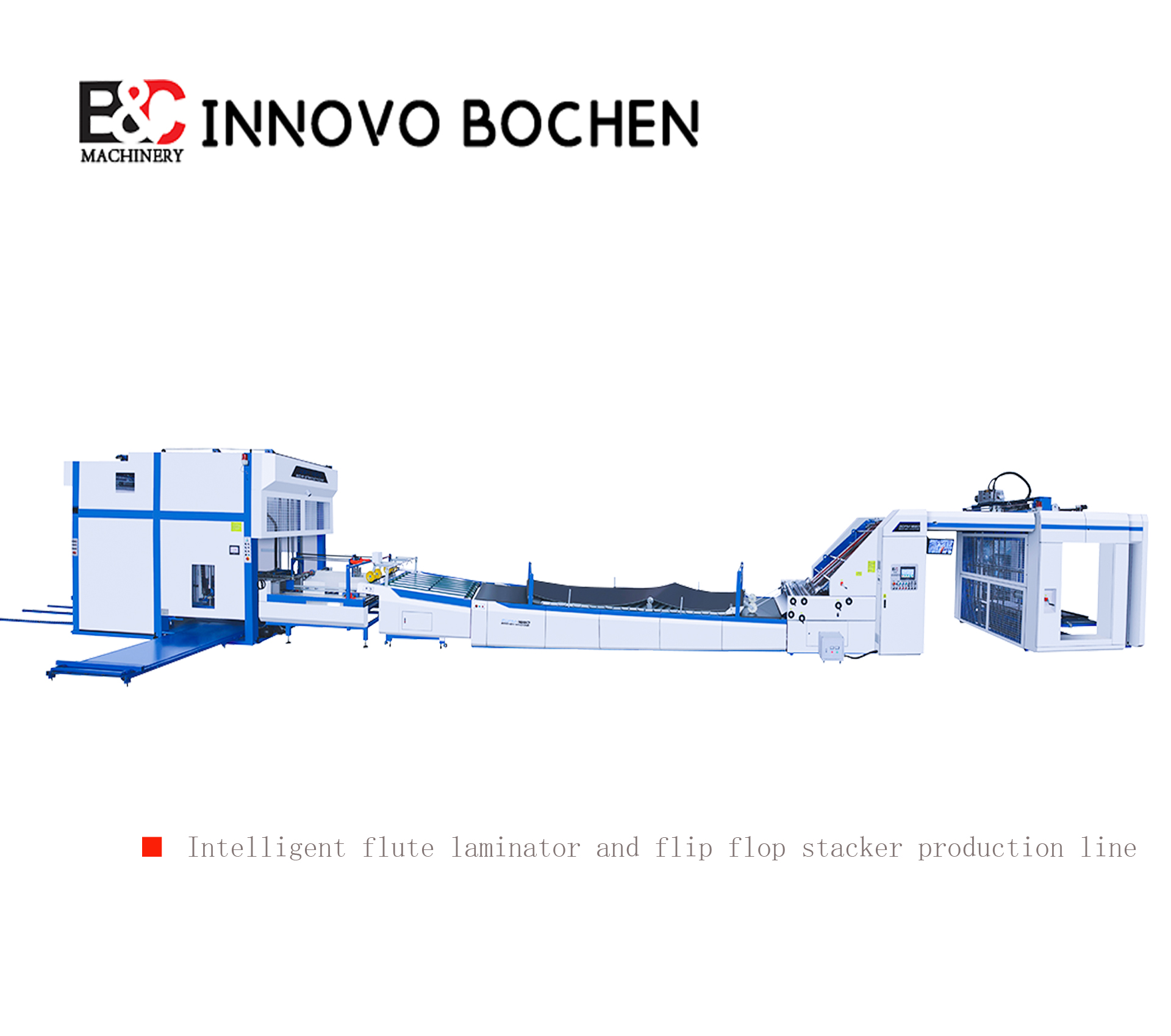

ZGFS-1450/1650 Automatic flute Paper Laminating Machine High Speed flute laminator Intelligent Automatic Flute Laminating

1.1 Function:

The paper can be laminated with paperboard to increase the strength and thickness of the material or special effects. After the die-cutting, it can be used for packaging boxes, billboards and other purposes.

1.2 Structure:

A. Upper Paper Feeder: It can send stacks of 150-800gsm paper from above.

B. Bottom feed: It can send 0.5~10mm paperboard from below.

C. Gluing mechanism: The glued water can be applied to the fed paper.

D. Regulatory organization - Fits the two papers according to the set tolerances.

E. Pressurizing Conveyor... Presses the attached paper and conveys it to the delivery section.

1.3 Principles:

The top paper is sent out by the upper paper feeder and sent to the start detector of the positioning mechanism for detection. Then the bottom paper is sent out; after the bottom paper is coated with glue on the glue wheel, the top paper and the bottom paper are respectively conveyed to the paper Synchronous detectors on both sides, after the detection, the controller calculates the error value of the paper and the bottom paper, and the servo compensation device on both sides of the paper compensates the paper to a predetermined position for splicing, and then pressurizes the conveying. The machine presses the paper and conveys it to the delivery machine to collect the finished product.

1.4 applicable materials:

Paste paper --- 150 ~ 800g/m thin paper, cardboard.

Bottom paper---0.5~10m/m paperboard, single-sided cardboard, multi-layer corrugated paper, pearl board, honeycomb board, styrofoam board.

Glue - resin, etc., PH value between 6 ~ 8, can be applied to the glue.

Structural features:

1. Adopting the world's leading transmission control system, only need to input paper size system auto-tuning.

2. Computerized high-speed fitting, up to 12,000 pieces per hour.

3. Chuanliu-type air supply head, with four sets of forward nozzles and four sets of suction nozzles.

4. Feed Block adopts low stack cardboard, which can fit the paper to the pallet, and can install track-assisted pre-stacker

5. Use multiple sets of electric eyes to know the advance position of the bottom line, and make the servo motor on both sides of the face paper to independently rotate to compensate the upper and lower paper alignment, which is accurate and smooth.

6. Full-function electronic control system, using human-machine interface and PLC program model display, can automatically detect operating conditions and work records.

7. Automatic glue replenishment system can automatically compensate for lost glue and cooperate with glue recycling.

Parameters:

| Model | ZGFS1450 | ZGFS1650 |

| Max size | 1450*1450mm | 1650*1650mm |

| Min size | 450*450mm | 450*450mm |

| Paper | 150-800g | 150-800g |

| Bottom paper | ≤10mm ABCEF corrugated board | ≤10mm ABCEF corrugated board |

| Max speed | 12000pcs/h | 12000pcs/h |

| Power | 25kw | 27kw |

| Stick accuracy | ±1.5mm | ±1.5mm |

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.