Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

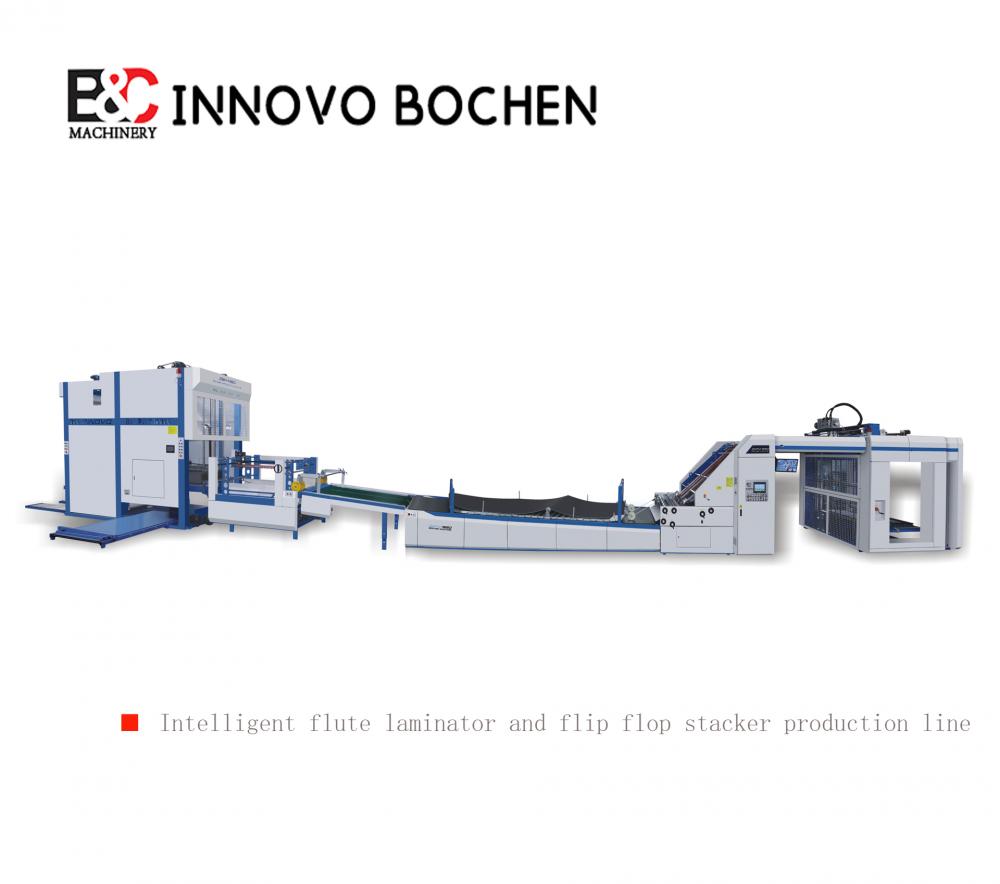

Product Description

Product Attributes

Model No.: ZGFH1450

Applicable Industry: Advertising Company, Printing Shops, Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Retail, Energy &Amp; Mining

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 2 Years

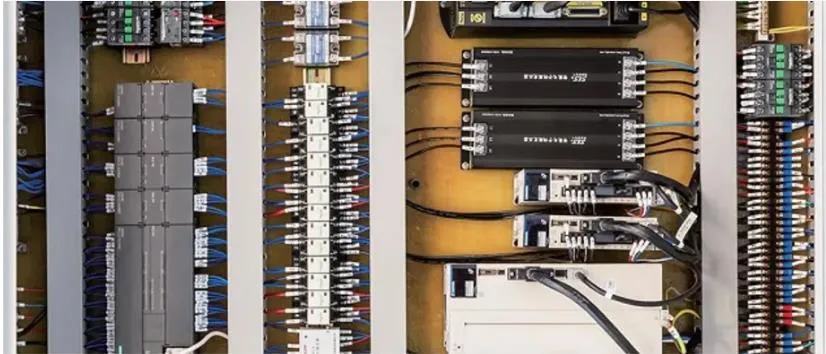

Core Components: Plc

Status: New

Degree Of Automation: Automatic

Place Of Origin: China

Warranty Period: 2 Years

Core Selling Point: Automatic, High Productivity

Top Sheet Thickness: 150-800g/m²

Bottom Sheet Thickness: paper thickness≤10mm

Working Speed: 160m/min

Accuracy: ±0.8mm

Total Power: 33KW/38KW

Supply Ability & Additional Information

Packaging: Wooden Case

Payment Type: L/C,T/T

Incoterm: CFR,FOB,CIF,EXW

Product Description

| Model | ZGFM1500 | ZGFM1700 | ZGFM1900 | ZGFM2200 |

| Maximum paper | 1500*1500mm | 1700*1700mm | 1900*1900mm | 2200*2200mm |

| Minimum paper | 360*380mm | 360*400mm | 500*500mm | 500*500mm |

| Top sheet thickness | 150-800g/m² | 150-800g/m² | 150-800g/m² | 150-800g/m² |

| Bottom sheet thickness | paper thickness<=10mm | paper thickness<=10mm | paper thickness<=10mm | paper thickness<=10mm |

| Working speed | 160m/min | 160m/min | 160m/min | 160m/min |

| Accuracy | ±0.8mm | ±0.8mm | ±0.8mm | ±0.8mm |

| Total power | 20KW | 20KW | 22KW | 22KW |

| Dimension | 14800*2300*2400mm | 15800*2500*3520mm | 16500*2748*3520mm | 17900*2960*3520mm |

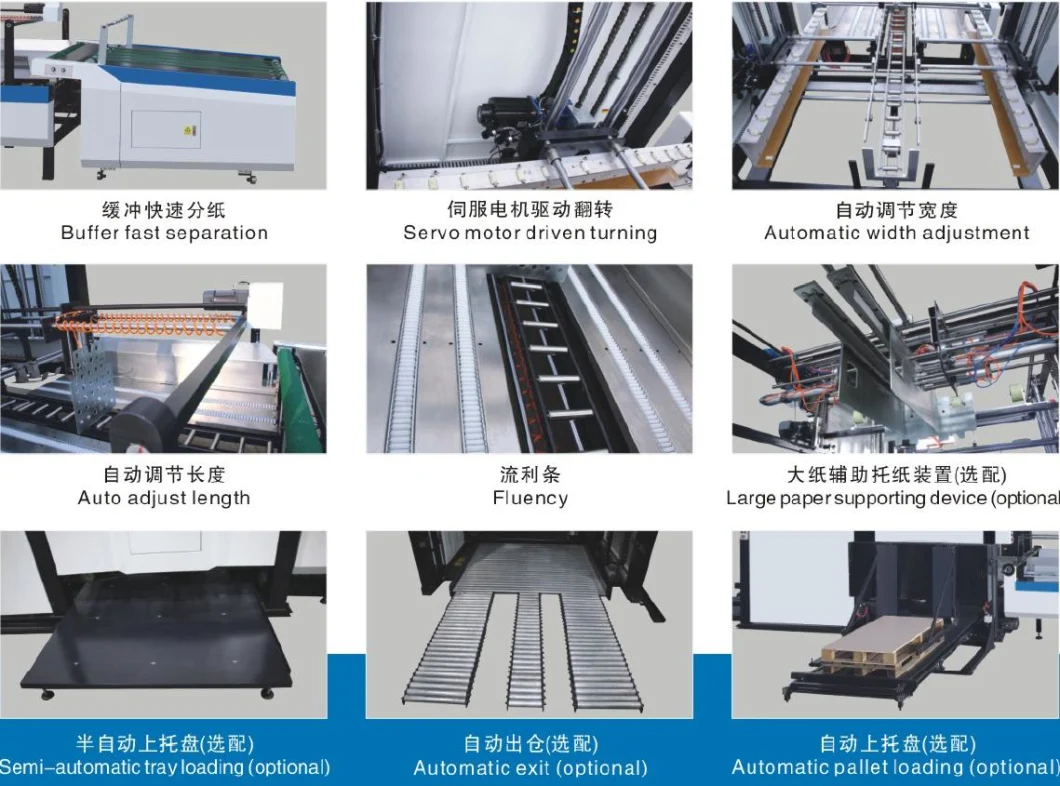

BOTTOM PAPER FEEDING:

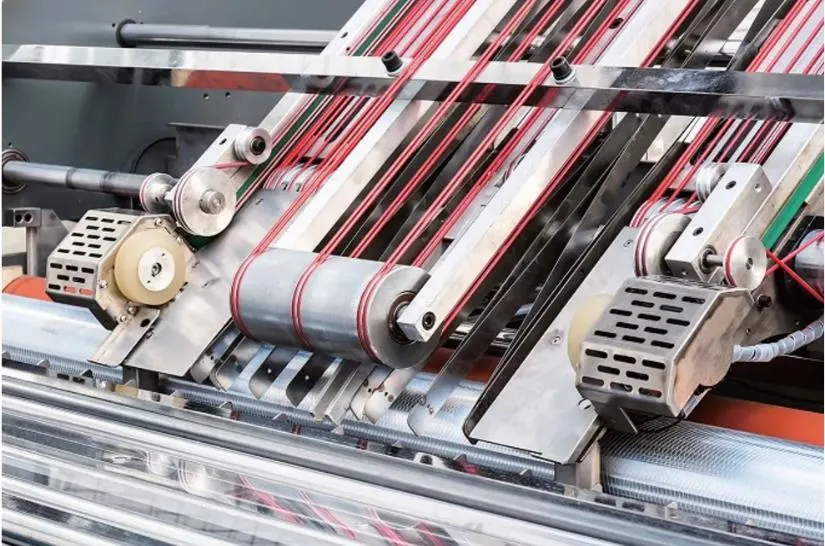

Use imported Servo motor electric controlling system, with Japan NITTA suction belt to make suction power inverter, and belt cleaned by water roller, Patented technology to ensure corrugate and cardboard goes out smoothly and simple operation.

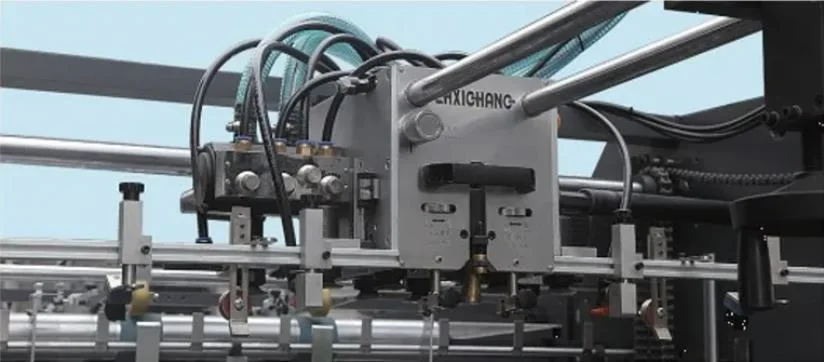

TOP SHEET FEEDING MECHANISM:

Equipped with high speed auto dedicated feeder, both paper lifting and feeding nozzle can freely adjust angle to the paper, to ensure that whether thick or thin paper can be delivered rapidly and smoothly.

ELECTRICAL SYSTEM:

Designed in the accordance with European CE requirement, ensure machine stability, high efficiency and low failure. Using man-machine interface and PLC combination, display all the information, such as warning, error detect, failures, and operating speed, etc on the screen at a glance.

PRE-STACK PART:

Pre-stack pile of paper under the condition of non-stop, improve efficiency. The special design of the pre stack paper frame, save time and effort.

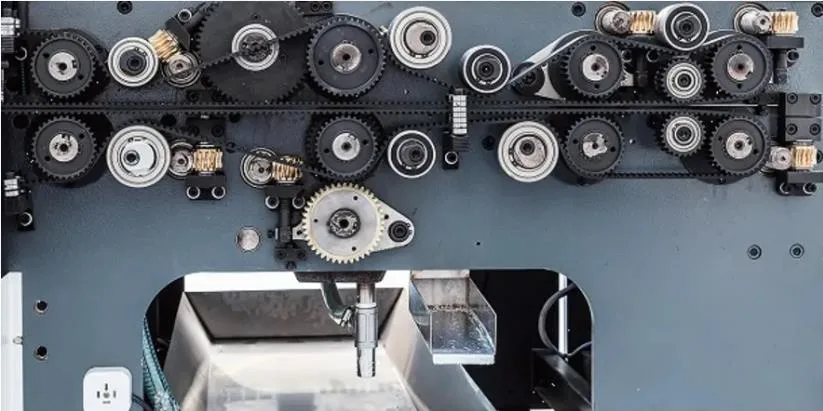

TRANSMISSION:

With imported double teeth belt drive and Switzerland ROSTA tension device ensure the drive accurate, stable and low noisy.

POSITIONING SYSTEM:

The use of multiple sets of photoelectric sensor at bottom sheets relative position, control top sheets on both sides of the servo motor to do independent compensation action, so that accurate positioning of top paper and the bottom paper.

GLUE ROLLER:

Stainless steel roller,never rust, after narrowly grinding, guaranteed the minimum amountglue coated evenly. Down roller be cleaned by water roller.

LEADING EDGE FEEDING SYSTEM(OPTION)

This system is for option,more suitable for large size and thick bottom sheets.

| Model | ZSH1500 | ZSH1700 | ZSH1900 | ZSH2200 |

| Maximum Paper | 1500*1500mm | 1700*1700mm | 1900*1900mm | 2200*2100mm |

| Minimum Paper | 420*450mm | 420*450mm | 420*450mm | 420*450mm |

| Power | 8KW | 8KW | 16KW | 16KW |

| Machine weight | Around 4000kg | |||

| Production Speed | 12000pcs/h(E flute) | |||

| Volatge | 380VAC/3P | 380VAC/3P | 380VAC/3P | 380VAC/3P |

| Air Pressure | 0.65-0.85Mpa | 0.65-0.85Mpa | 0.65-0.85Mpa | 0.65-0.85Mpa |

| Dimension | 10600*2400*2750mm | 11400*2600*2950mm | 13000*2700*2950mm | 13800*2900*2950mm |

Company Overview

Anhui Innovo Bochen Machinery Manufacturing Co., Ltd. is a global business enterprise engaged in the manufacture, marketing, research and development of machinery. Our firm also provides import and export operations and technical training. We are a professional firm which manufactures and sells printing machines and office equipment. Our high quality products and perfect service have enjoyed a high reputation in the industry. Moreover, they sell well all over the world. Our products include all kinds of offset machines, cutting machines, binding machines, bill printing machines, digital stencil duplicator machines, digital print machines, spray printing machines, print finishing machines and other kinds of printing, packing, advertisement and office equipment. We sincerely hope to establish business relationships and cooperate with you.

Our tenets:

1) Society`s Avail First

2) Client`s Avail First

3) Employee`s Avail First

4) Enterprise`s Avail Second

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.