Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: ZX-A4

Brand: INNOVO

Applicable Industry: Printing Shops, Energy &Amp; Mining, Construction Works, Machinery Repair Shops, Advertising Company, Retail, Manufacturing Plant, Food Shop, Building Material Shops, Garment Shops, Restaurant, Food &Amp; Beverage Factory, Home Use

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Status: New

Product Category: Other

Processing Type: Cutting Machine

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Productivity: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc, Motor, Pump

Paper Width: Gross width 850mm, net width 840mm

Cutting Numbers: 2 cutting-A4 210mm (width)

Paper Roll’s Diameter: Max.Ф1450mm. Min.Ф600mm

Name: A4-2(pocket) Cut Size Sheeting Machine

Packing Paper Grade: High-grade copy paper; High-grade office paper; High grade Free Wood paper etc.

Paper Weight: 60-100g/m2

Sheet Length: 297mm ( specially design for A4 paper, the cutting length is 297mm)

Ream Amount: 500 sheets Max. Height: 45-55mm

Production Speed: Max 0-200m/min(depends on different paper quality)

Max. Numbers Of Cutting: Max841/min

Supply Ability & Additional Information

Packaging: Wooden case

Productivity: 20sets/month

Transportation: Ocean

Place of Origin: Anhui,China

Supply Ability: 20sets/month

HS Code: 8441100000

Port: Ningbo,Shanghai

Payment Type: T/T,L/C

Incoterm: FOB,CFR,CIF

Product Description

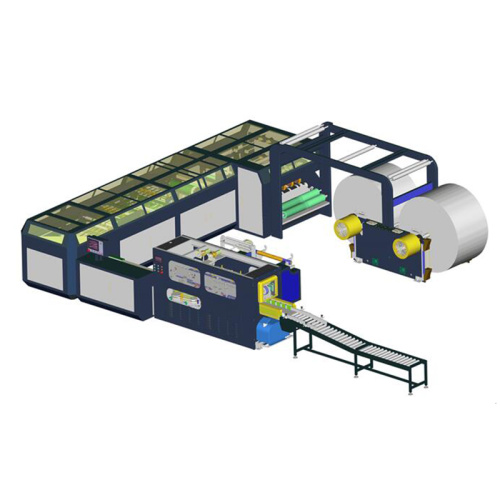

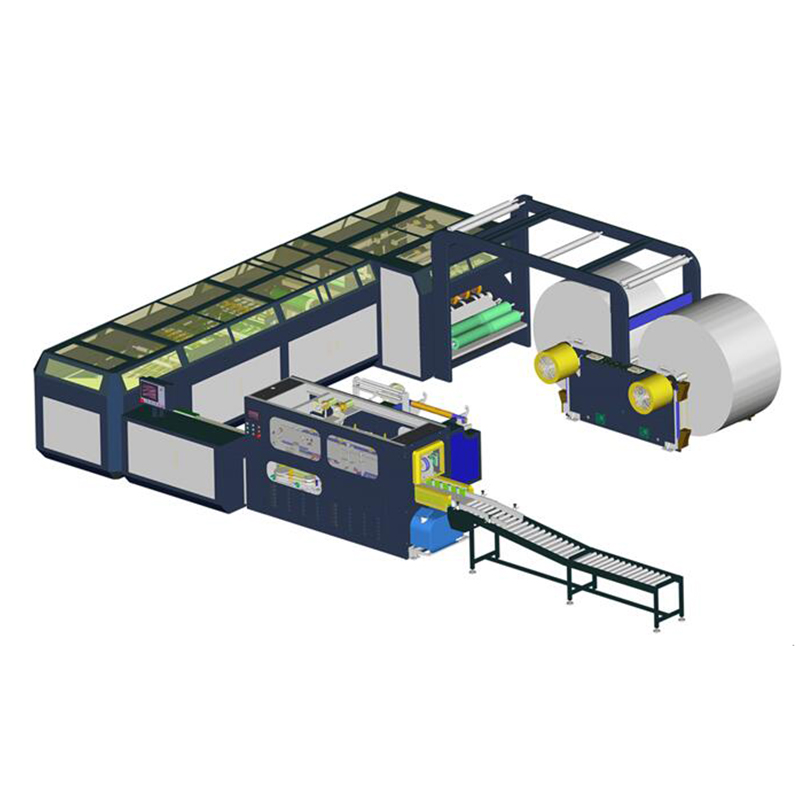

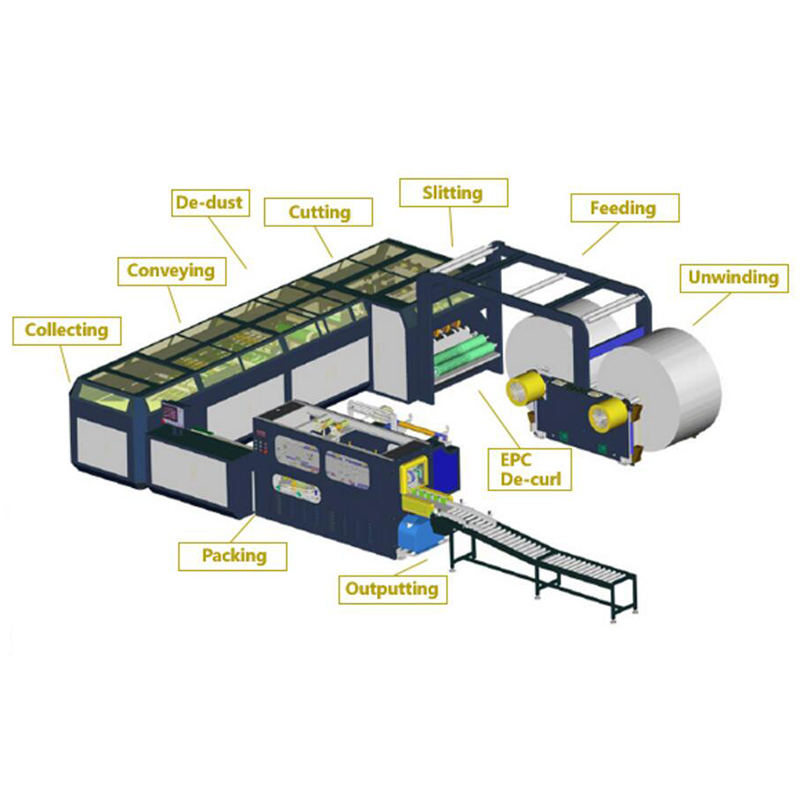

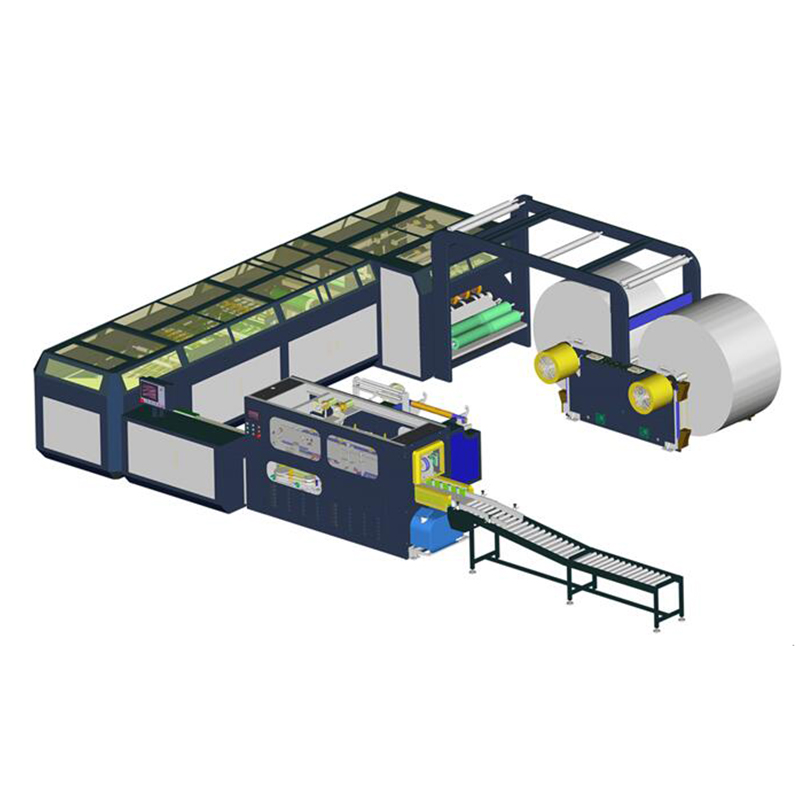

A4 copy paper production line

SPECIFICATION

2.1. Technics of Equipment

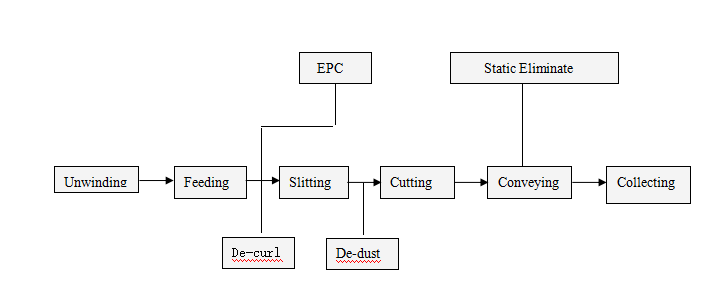

As technics of our machine, we hereby describe the related functions and work flow for paper products: unwinding→ cutting → conveying → collecting → Packaging.

![]()

A. A4-2(pocket) Cut Size Sheeting Machine

A.1. Main Technical Parameter

| Paper Width | : | Gross width 850mm, net width 840mm |

| Cutting numbers | : | 2 cutting-A4 210mm (width) |

| Paper roll’s diameter | : | Max.Ф1450mm. Min.Ф600mm |

| Paper core’s diameter | : | 3”(76.2mm)or 6”(152.4mm) or according to the clients’ demand |

| Packing Paper grade | : | High-grade copy paper; High-grade office paper; High grade Free Wood paper etc. |

| Paper weight | : | 60-100g/m2 |

| Sheet length | : | 297mm ( specially design for A4 paper, the cutting length is 297mm) |

| Ream amount | : | 500 sheets Max. Height: 45-55mm |

| Production speed | : | Max 0-200m/min(depends on different paper quality) |

| Max. Numbers of cutting | : | Max841/min |

| Output of the ream | : | Max 13reams/min |

| Load of cutting | : | 100g/m2 (1×100g/m2) |

| Cutting accuracy | : | ±0.2mm |

| Cutting condition | : | No variation of the speed, no break, cut all the paper at one time and need the eligible paper. |

| Main power supply | : | 3*380V /50HZ |

| Voltage | : | 220V AC /24V DC |

| Power | : | 23KW |

| Air consumption | : | 200NL/min |

| Air pressure | : | 6 bar |

| Edge cutting | : | 5~15mm×2 |

| Safety standard | : | Design according the safety standard of China |

A.2.Standard Configuration

1. Unwind Stand (1Sets= 1Rolls)

A-1 Type: CHM-A4-2

| 1) Machine Type | : | Each machine table can take 2 sets of shaftless paper rack. |

| 2) Diameter of the paper roll | : | Max. Ф1450mm |

| 3) Width of the paper roll | : | Max. Ф850mm |

| 4) Paper rack’s material | : | Steel |

| 5) Clutch device | : | Pneumatic Braker and control |

| 6) Clip arm’s adjustment |

| Manual adjust by oil pressure |

| 7) Paper core demanding |

| 3”(76.2mm) air expansion shaft chuck |

2. Automatic tension control system

A-2 Type: Automatic tension control system

| 1) When the paper through inductor, that automatic feedback to the PLC control system to increase brake load, increase or reduce the tension that control the paper tension automatically. |

3 High precision cutting knife system

A-3 Type: High precision cutting knife system

| 4) Paper feeding wheel |

|

|

| Upper wheel | : | Ф200*550mm (rubber covered) |

| Lower wheel | : | Ф400*550mm (anti-glide) |

| 5) Cutting knife group |

|

|

| Upper cutting knife | : | 1 sets 550mm |

| Lower cutting knife | : | 1 sets 550mm |

| 6) Driving group(High precision bear and belt drive) | ||

| 7) Main driving motor group: 15KW | ||

4. Transporting System

A-4.Type: Transporting system

| 1) Transporting by level and overlapping device |

| 2) High speed transporting belt and press wheel. Upper and lower transport belt corresponding pressure paper, automatic tension and close system. |

| 3) Static removal device(Include static removal bar and Negative ion generator) |

5. Paper collecting system

A-5 Type: Paper collecting system

1) Automatic device for paper stack up and down

2) Jogging device and clap paper tidy. Control by air vat, when design

sheet, the cylinder up and down by cut paper bar. After transport paper

to belt, transport to the pack table cross.

6. Accessories

A-6 Type: Accessories

| Upper knife | : | 1 sets 550mm Material: compounding of tungsten steel |

| Lower knife | : | 1 sets 550mm Material: compounding of tungsten steel |

| Upper slitting knife | : | 5 sets Ф180mm Material: SKH |

| Lower slitting knife | : | 5 sets Ф200mm Material: SKH |

B. CHM-A4B Wrapping Machine

B.1. Main Technical Parameters:

| Paper Width | : | Gross width:310mm ;net width :297mm |

| Ream packing high | : | Max 55mm ; Min 45mm |

| Packing roll dia | : | Max.1000 mm ; Min.200mm |

| Packing roll width | : | 560mm |

| Packing sheets weight | : | 70-100g/m2 |

| Packing sheets grade | : | high-grade copy paper, high-grade office paper, high-grade offset paper etc. |

| Design speed | : | Max 50 reams/min |

| Operation Speed | : | Max 35 reams/min |

| Packing condition | : | no speed variations, no breaks, cut all the paper at one time and qualified packing paper. |

| Driving | : | AC Servo Precision Control |

| Main power supply | : | 3*380V /50HZ( or as required) |

| Voltage | : | 220V AC /24V DC (or as required) |

| Power | : | 18KW |

| Compressing air consumption | : | 300NL/min |

| Air pressure | : | 6bar |

B.2. Configuration:

| 1. Conveyer system for reams placement ( 800*1100) | : | One set |

| 2. Ream accelerated to placing system | : | One set |

| 3. Unwind stand for packing roll | : | One set |

| 4. Lifting system for reams | : | One set |

| 5. Pressing and tighten system for reams | : | One set |

| 6. Lower folding system for packing sheets | : | Two sets |

| 7. Angle overlapping system for packing sheets | : | One set |

| 8. Steadfastness angle overlapping for packing sheets | : | One set |

| 9. Spraying hot melt glue system for packing sheets | : | One set |

| 10. PLC system for alarming, auto stop of break-down | : | One set |

| 11. PLC controlling system | : | One set |

C. All the machine is controlled by PLC.

Included the following function: speed control, paper count, paper ream output, fault alarm and automatic stop(Indicate fault code shown on the panel screen)

D. Prepare items by buyer

1)The civil engineering and substructure of this machine

2)The machine main power wiring and electric line setting work out of this machine control box.

3)Air pressure source and pipe for this machine.

4)The suspend and unload work at scene.

E. Other terms

This machine design by the newest technical and technology development, so in the ruler of not effect the production and quality, we remain the right to modify and change.

Company Overview

Anhui Innovo Bochen Machinery Manufacturing Co., Ltd. is a global business enterprise engaged in the manufacture, marketing, research and development of machinery. Our firm also provides import and export operations and technical training. We are a professional firm which manufactures and sells printing machines and office equipment. Our high quality products and perfect service have enjoyed a high reputation in the industry. Moreover, they sell well all over the world. Our products include all kinds of offset machines, cutting machines, binding machines, bill printing machines, digital stencil duplicator machines, digital print machines, spray printing machines, print finishing machines and other kinds of printing, packing, advertisement and office equipment. We sincerely hope to establish business relationships and cooperate with you.

Our tenets:

1) Society`s Avail First

2) Client`s Avail First

3) Employee`s Avail First

4) Enterprise`s Avail Second

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.