Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Description

Product Attributes

Model No.: ZX-1650

Brand: INNOVO

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Printing Shops

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Not Available

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Core Components: Plc, Motor

Status: New

Application: Machinery &Amp; Hardware

Type Of Packaging: Cartons

Packaging Materials: Wood

Degree Of Automation: Automatic

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Supply Ability & Additional Information

Packaging: Export wooden box packaging

Productivity: 8 Sets/Months

Transportation: Ocean

Place of Origin: ANHUI

Supply Ability: 8 Sets/Months

Port: Ningbo Port,Shanghai Port

Payment Type: T/T

Incoterm: FOB,EXW

Packaging & Delivery

Product Description

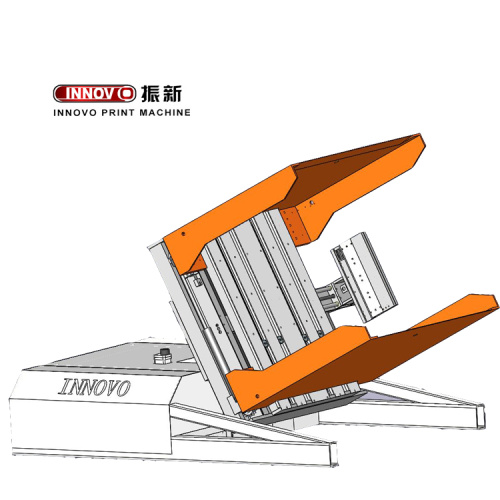

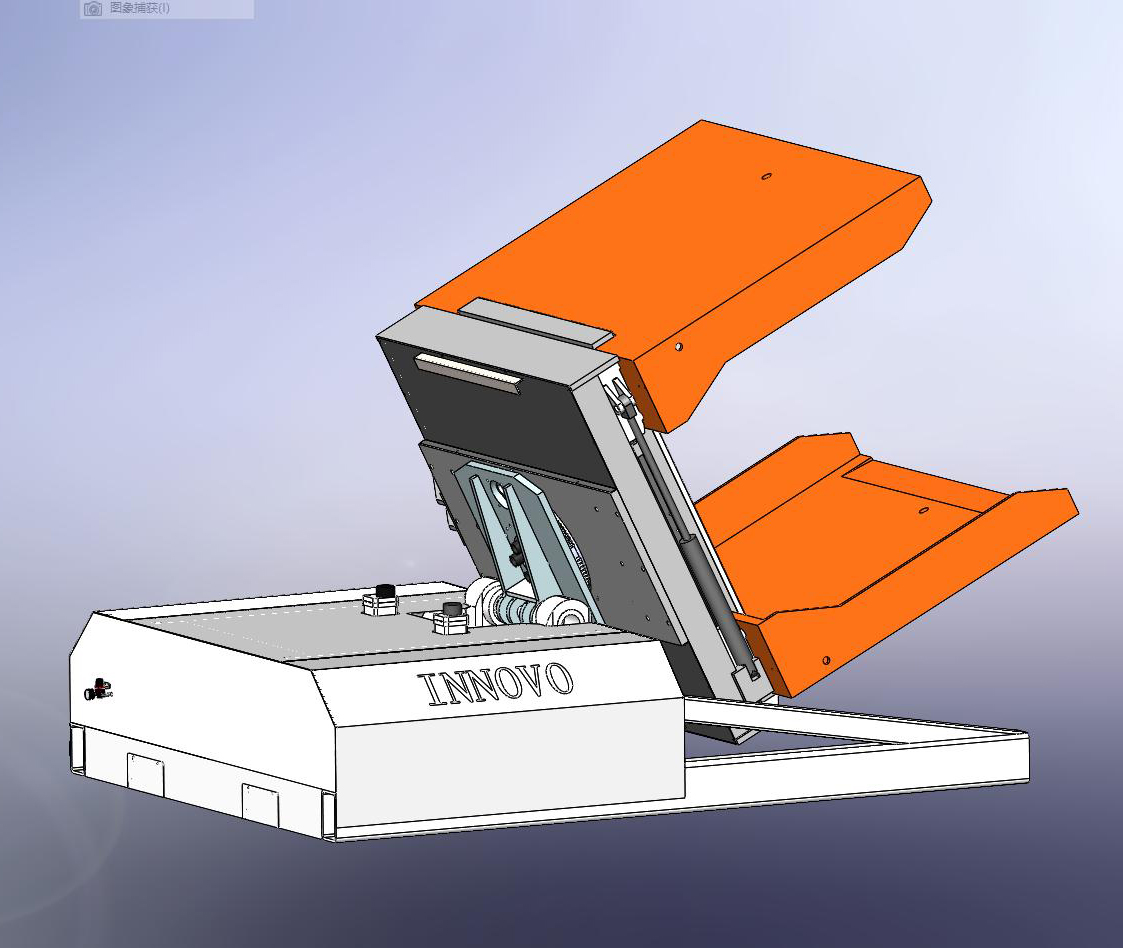

Full Automatic pile turner for paper and plastic

Product description

The printing industry at present, a new generation of Printing Machine operator has more reluctant to engage in high intensity of labor jobs(such as paper-pile flip, etc.), and the labor cost is higher and higher in recent years. Printing and packaging enterprises are the trend of the times to equip with paper-pile flip sorting machine in processing of sheet -fed printing and packaging, etc. Whereasin Occident, average two sets of sheet-fed printing will equip a set of paper-pile flip sorting machine. Our company combined with the advanced technology of foreigh products, through years of development and testing, now our new product has a fothold in the market. Our company goal is to make most of printing enterprises strive to equip a set of paper-pile flip sorting machine for every three sets of printing press, in order to reduce the labor intenity, enhances the working efficiency in printing enterprise.

Use before printing

Alignment: When the paper stack is tilted, the wind is blown through a large air volume, and the paper is quickly aligned with the efficient vibration. In this process, the damaged paper can be removed to ensure a neat stack.

Dust removal: It can remove impurities such as paper wool and paper scraps, improve the surface quality of the paper to be printed, and reduce the possibility of double-feeding

Efficiency: Due to the improvement of the surface quality of the paper, the speed of the printing press can be increased by 3-5%, which improves the labor productivity

Long-term effect: greatly reduce the entry of impurities such as paper wool and paper scraps into the printing press, and extend the life of the printing press

Finished product: the rate of waste and defective products due to impurities such as paper wool and paper scraps can be reduced, and the finished product rate can be increased by 2-3%

Use after printing, transfer station, paper cutting and die cutting

Drying: It can remove powder spray, accelerate ink drying, and at the same time quickly reduce the smell of printed sheets due to the ink solvent, prevent the occurrence of quality problems such as sticking and smudging behind, and save a lot of manpower

Main features:

1. To promote post-printing process efficiency.

2. To maintain the highly efficient production capacity of the printer.

3. To finish the paper-pile rollover in one minute.

4. To finish the paper-pile aligning, dust removing and rollover within 4-5 minutes on average.

5. To do operation without professtional staff.

Parameters:

| Model | ZX-1650 |

| Max sheet size | 1220*1650mm |

| Loading weight | 1900kg |

| Platform width | 1800mm |

| Platform depth | 1235mm |

| Max pile height | 1600mm |

| Min pile height | 830mm |

| Power | 17kw |

| Length | 2790mm |

| Width including operating rod | 2060+1340mm |

| Height | 2260mm |

| Machine weight | 4500kg |

Workflow:

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.